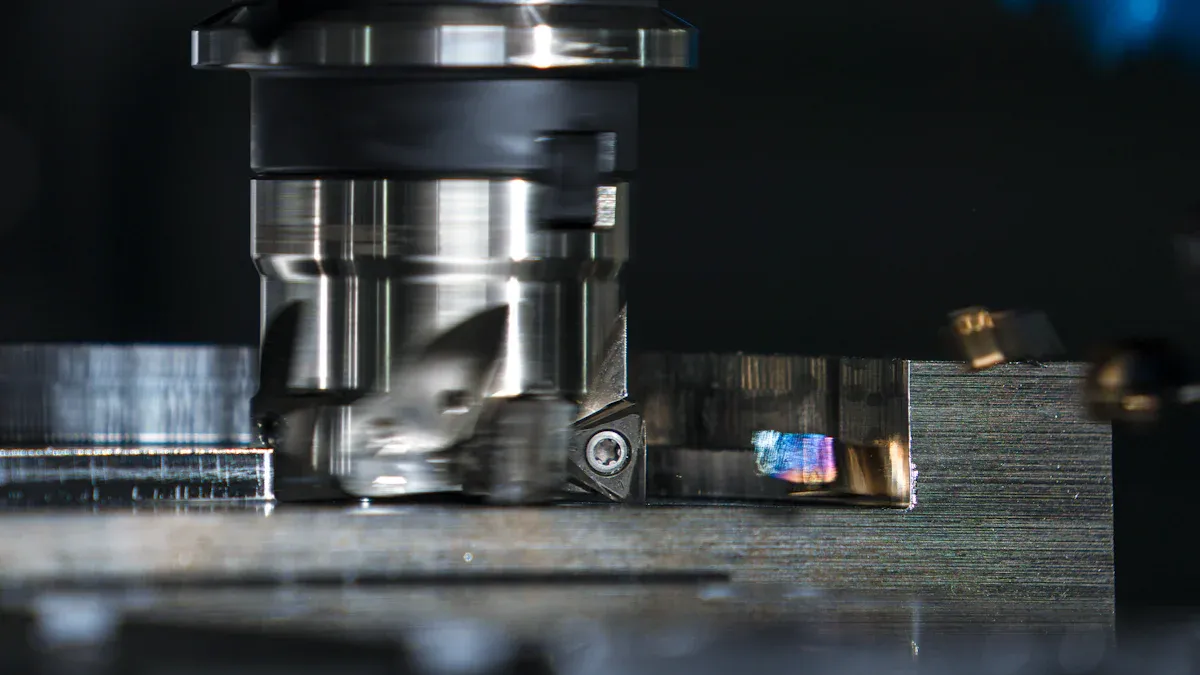

Custom end mill solutions for stamping dies boost precision, surface quality, and tool life, solving challenges with complex profiles and hard materials.

Reading volume: 770

Release time :2025-09-25

Estimated reading time:

Custom end mill solutions for stamping dies boost precision, surface quality, and tool life, solving challenges with complex profiles and hard materials.

You can make stamping dies work better with special milling solutions. A custom end mill fits your needs, so you get more accuracy and work faster. Tool experts make custom tools to fix problems like small spaces or tough materials. Custom end mills help you solve usual stamping die problems.

l The right end mill makes surfaces smoother. This means less waste and better parts.

l Custom end mills last longer. They save you time and money. You do not stop work as much. You can make more parts faster.

l Picking good materials and coatings for end mills is important. It helps them work better and last longer.

l Working with tool makers gives you better custom solutions. Your needs are met in the best way.

l You want your stamping dies to work with high accuracy. Custom end mills help you reach this goal. These tools fit your exact needs, so you can repair or shape dies with great care.

l Custom end mills let you fix worn or damaged parts of a die. You can restore the shape and keep the die working like new.

l In one case, a carbide end mill repaired a worn cavity surface. The result was a smooth finish of Ra 0.4 µm. This level of precision removed defects and cut downtime by 60%.

l Another example used a 4-flute end mill to restore a die-casting mold’s gate. This improved how metal flowed and made the mold last 50,000 more cycles.

l You can also use a solid carbide end mill to machine out cracks in tough steel molds. This keeps your stamping dies precise and ready for use.

l A smooth surface on your stamping die means better parts and less waste. Custom end mills give you control over the finish. You can choose the right tool for each job, so you get the best results every time.

l Custom end mills adapt to different materials and shapes. This means you can keep the surface quality high, even on complex dies.

l When you use the right end mill, you avoid rough spots and keep your dies in top shape.

You want your tools to last as long as possible. Custom end mills help you reach this goal.

These tools match your die’s material and shape, so they wear out slower.

A high-performance end mill can save you time and money. For example, saving two minutes per part on a 100-piece order can mean $333 in cost savings.

The money you spend on custom tools pays off because you get more parts and less downtime.

Tip: Custom end mills not only improve your die quality but also help you save money and reduce machine stops.

You can pick from many materials for your end mill. Each one has its own good points. Some are better for hard metals. Others help you save money or last longer. Here is a table that lists the most common materials and what they do:

Material Type | Properties |

Carbon Tool Steel | Good processability, low price, but poor hardenability and red hardness. |

Low Alloy Tool Steel | Improved hardenability and wear resistance, reduced quenching deformation. |

High Carbon High Chromium Steel | Good hardenability and wear resistance, minimal heat treatment deformation. |

High-Speed Steel | Highest hardness and abrasion resistance, excellent bearing capacity. |

Cemented Carbide | High hardness and wear resistance, but poor bending strength and toughness. |

Steel-Bonded Cemented Carbide | Better toughness and machinability than cemented carbide, still high hardness and wear resistance. |

Solid carbide is great for hard jobs. It is very hard and resists wearing out. If you need a tougher tool, steel-bonded cemented carbide is a good choice. You should pick the material that matches your stamping die and the job. This helps your end mill work its best.

You can put coatings on your end mill to help it last longer. Coatings protect your tool from heat and wearing out. They also help chips move away from the cutting spot, which keeps things cool.

Coatings help your end mill stay sharp during hard jobs.

They move chips away fast, so your tool does not get too hot.

New coatings make your tool last longer and work faster.

Some coatings you might use are:

TiN (Titanium Nitride): This makes your tool work better and last longer.

TiCN (Titanium Carbonitride): This is tougher than TiN and helps with abrasion. You can use it for milling steels and stainless steels.

TiAlN (Titanium Aluminum Nitride): This keeps its hardness even when it gets hot. It works well for many jobs.

You should choose the coating that fits your stamping die material. The right coating helps your end mill last longer and work better.

Tip: Coated solid carbide end mills give you less friction and more heat resistance. This means you get smoother cuts and your tool lasts longer.

You can change the shape of your end mill to fit your needs. Geometry means how the tool is shaped and designed. You can pick how many flutes it has, the core shape, and the rake angle.

Negative rake designs help you cut hard stuff with less force.

Heavy core end mills are stronger and more stable. You can use them for deep cuts or tough metals.

More flutes give you smoother finishes. Fewer flutes help chips move away faster.

You should match the geometry to your stamping die and the job. This helps you get the best results and avoid problems like tool breakage or rough surfaces.

Note: Changing the geometry of your end mill helps you fix problems like tight spaces, tricky shapes, or hard-to-machine materials.

You often face stamping dies with complex shapes and tight spaces. Standard tools may not give you the accuracy you need. Custom end mills help you machine these tricky profiles with ease. You get tools made for your exact die shape, so you can reach every corner and curve.

Here is a table that shows how custom end mills compare to standard tools for complex profiles:

Aspect | Custom End Mills | Standard Tools |

Design | Made for intricate shapes | General-purpose |

Precision | High accuracy for unique parts | May lack needed precision |

Efficiency | Faster and more efficient for complex profiles | Slower and less efficient |

Industry Application | Used in industries needing complex geometries | Best for simple, standard jobs |

Profile milling lets you create detailed shapes in your dies. This process is important in industries like aerospace and automotive, where you need parts with exact dimensions.

Stamping dies often use hard metals. These materials can wear out your tools quickly. Custom end mills solve this problem by using special materials and shapes. You can pick a tool that works well at slower speeds, which helps your tool last longer and keeps costs down.

l Hard metals need slower cutting speeds to reduce tool wear.

l Tool costs can be high. Carbide inserts cost $15-25, ceramic inserts $40-80, and CBN tools over $200 per edge.

l You may need to change tools often, which can slow down your work and raise costs.

l Ball end mills work well for finishing hard metals. They spread heat better and lower the risk of deforming your die.

l Using larger radii in corners lets you use standard tools, but sharp corners can cause shock loads and damage in hard materials.

Burrs are small, unwanted pieces of metal left after cutting. They can ruin the surface of your stamping die and cause problems in your finished parts. Custom end mills help you avoid burrs. These tools use advanced shapes and coatings to cut cleaner and leave a smoother finish. You get fewer burrs, which means less time spent cleaning up your dies and better quality parts.

Tip: Choosing the right end mill for your die helps you handle tight tolerances, tough materials, and burr control all at once.

First, you need to know what your stamping die needs. This helps you pick the right tool for your job. Check how thick the material is. See if the gauge changes or stays the same. Look at what the material is made of. Hardness and ductility are important. The surface can change how you cut. Think about how many parts you want to make each year. Batch sizes help you plan better. Look at your quality rules. Tolerances and surface finish needs help you choose.

l Material thickness

l Material composition

l Production needs

l Quality rules

A clear check helps you choose the best end mill for your stamping die.

You should work with tool makers closely. Tell them what your die needs and your production goals. Good talking helps you get a tool that fits. Some companies, like Emuge Franken Group, know a lot about custom milling solutions. They listen to your problems and suggest designs that help. You can ask for advice about tool shape, coatings, and materials. Working together gives you better results and fewer mistakes.

Tip: Bring your engineers and tool experts together early. You get faster answers and better ideas.

Testing makes sure your custom tool works well. Start with a test run on a sample die. Measure the surface finish and look for burrs. Compare the results to your quality rules. If you find problems, change the tool design or cutting settings. Test again until you reach your goals. Write down each step. This record helps you do better next time.

Step | What You Do | Why It Matters |

Trial Run | Test on sample die | Find problems early |

Measure | Check finish and burrs | Meet quality rules |

Adjust | Change tool or settings | Make it work better |

Repeat | Test again | Make sure it improves |

You feel sure about your process when you test and improve your tools.

Custom end mills make it easier to fix stamping die problems. They help you get more accurate cuts and smoother surfaces. Your tools last longer, so you do not need to replace them as often. You can work faster and throw away less material. When you talk to tool makers, remember these things:

l Ask for tool ideas that match what you need.

l Tell them about your materials and what you want to make.

l Find ways to make your work faster and your parts better.

l Talk about how to fix problems and keep your machines running.

l You will get better results if you work with people who know what you need.

A custom end mill is a cutting tool made for your specific job. You choose the material, coating, and shape. This helps you get better results when you work with stamping dies.

You look at your stamping die’s hardness and the job you need to do. Use carbide for hard metals. Use high-speed steel for softer jobs. Check the table below for quick tips:

Die Material | Best End Mill Material |

Hardened Steel | Carbide |

Mild Steel | High-Speed Steel |

Stainless Steel | Carbide |

Coatings protect your tool from heat and wear. You get smoother cuts and longer tool life. Try TiN for general use. Use TiAlN for high heat jobs.

Pick an end mill with the right geometry and coating. Use sharp tools and adjust your cutting speed. You get cleaner edges and spend less time on finishing.

Tip: Always test your tool on a sample die before full production. This helps you catch problems early.

By continuing to use the site you agree to our privacy policy Terms and Conditions.