Reading volume: 1123

Release time :2025-10-15

Estimated reading time:

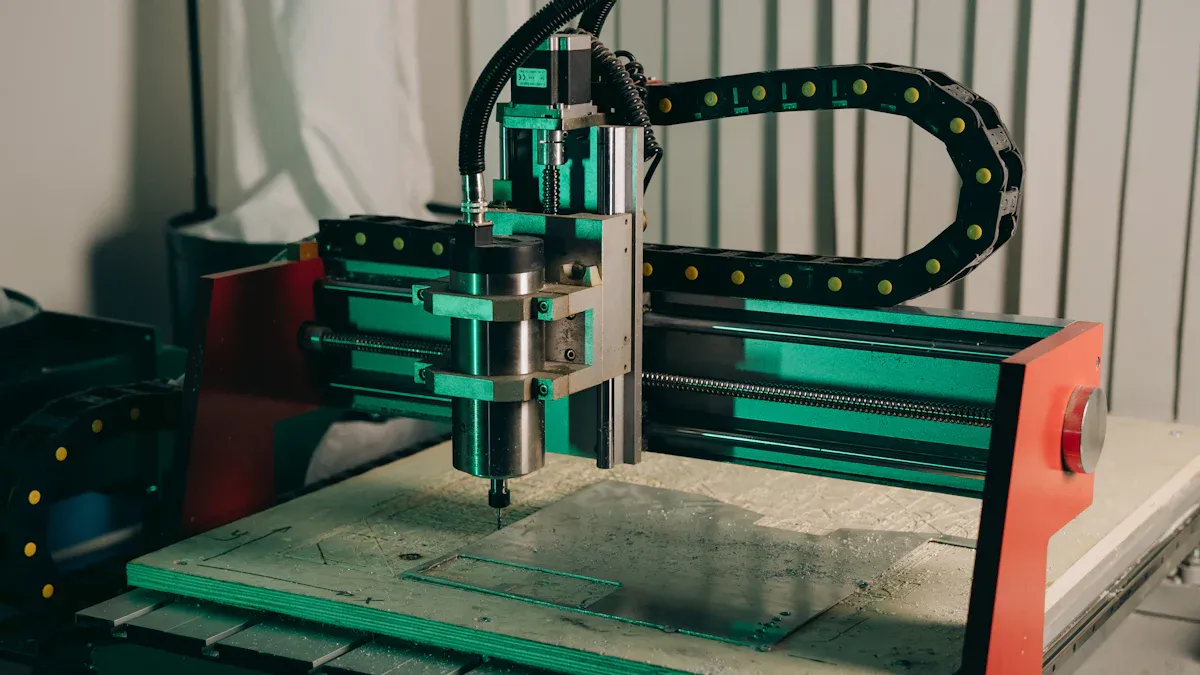

Choosing the right end mills can make or break your CNC project. You want smooth cuts, less vibration, and longer tool life. Take a look at how different end mill types boost efficiency:

End Mill Type | Application | Benefits |

Four-flute variable helix | Reduces vibrations | Longer tool life, better finishes |

Alumigator ASR5 | High-speed roughing and finishing | High metal removal rates |

PCD tooling | Non-ferrous applications | Great for aluminum castings |

When you know what works best, you get cleaner results and avoid costly mistakes.

l Choosing the right end mill type is crucial for achieving smooth cuts and extending tool life.

l Different end mills serve specific purposes; for example, roughing end mills remove material quickly, while finishing end mills provide a polished surface.

l Consider the material you are cutting; softer materials work best with 2-flute or 3-flute end mills, while harder materials require carbide tools.

l Pay attention to flute count; more flutes can improve finish quality, but fewer flutes are better for chip removal in deep cuts.

l Always match your tool's coating to the material and cutting conditions to enhance tool life and performance.

You might wonder what sets end mills apart in CNC machining. These tools are designed for cutting and shaping materials with precision. You can find them in many shapes and sizes, each built for a specific job. Take a look at how experts classify end mills:

Category | Description |

Classification by Shape | End mills include V-bits, square-end mills, ball end mills, and fishtail end mills. |

Classification by Flutes | You’ll see end mills with 2, 3, or 4 flutes. More flutes mean smoother finishes and better chip removal. |

Classification by Material | Common materials are High-Speed Steel (HSS), tungsten carbide, and cobalt. Each offers unique benefits. |

You can choose the right end mill by thinking about the shape, number of flutes, and material. This helps you match the tool to your project’s needs.

You may ask, “How do end mills differ from drill bits?” The answer comes down to design and motion. Here’s a quick comparison:

Feature/Application | End Mills | Drill Bits |

Design | Many flute designs for different materials | Simple design for round holes |

Motion | Cuts in many directions, including sideways | Moves up and down for boring |

Applications | Slotting, contouring, complex shapes | Makes holes in various materials |

Precision | Delivers smooth finishes and high accuracy | Creates holes quickly and accurately |

Versatility | Handles a wide range of jobs | Has specific types for different jobs |

Wear | Wears down faster | More durable for hole-making |

Tip: Use end mills for tasks like slotting and contouring. Drill bits work best for making holes.

You’ll see end mills in action across many industries. Here are some popular uses:

Healthcare: Making medical supplies and surgical instruments.

Energy: Shaping parts for wind turbines and pipelines.

Dental: Producing dental prostheses and trays.

Jewelry: Crafting rings, molds, and engravings.

Furniture: Cutting and designing furniture components.

End mills help you create detailed shapes, pockets, and engravings. You get the flexibility to tackle complex designs and achieve smooth finishes.

End mills are like the Swiss army knives of CNC machining. You can use them for many cutting operations, from shaping profiles to carving out slots. Each type brings its own strengths to your project.

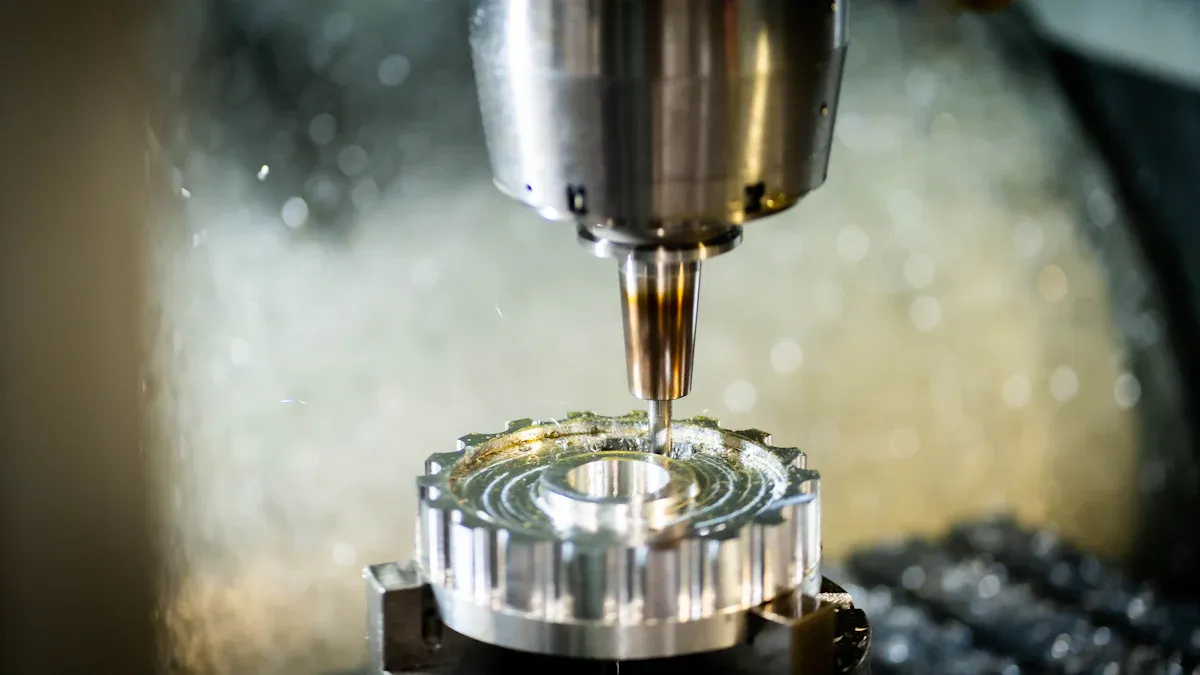

You want to remove a lot of material fast? Roughing end mills are your go-to tools. Their serrated edges break chips into small pieces, which lowers cutting forces and keeps the tool cool. You’ll see these used in mold making and metalworking, especially when speed matters. The wave-shaped edge helps prevent long chips and keeps your machine stable. In industries like aerospace, roughing end mills help you shape complex parts without causing distortion.

l High material removal rates

l Reduced heat and improved stability

l Shorter cycle times for big jobs

When you need a smooth surface, finishing end mills step in. These tools have more flutes, usually four to six, which means they leave a finer finish and clear chips better. Carbide finishing end mills hold their sharpness longer, and coatings like AlTiN help reduce friction and heat. You get crisp edges and a polished look.

Specification Type | Details |

Flute Count | 4-6 for smoother finishes |

Material | Carbide for sharpness and wear resistance |

Coating | AlTiN for less friction and better heat control |

Ball-nose end mills have a rounded tip. You’ll use these for 3D shapes and curved surfaces. The full radius lets you glide across complex contours without leaving sharp steps. If you work with 5-axis machines or need a high-quality finish on detailed parts, ball-nose end mills make the job easier.

l Smooth transitions on curves

l Great for 3D contouring

l No visible steps on rounded surfaces

Straight flute end mills work best on wood and plastics. They give you a smoother finish and help evacuate chips quickly. You can push them at higher feed rates, but the cutting edge isn’t as strong as other types.

Benefits | Limitations |

Improved chip evacuation | Weaker cutting edge |

Enhanced cooling | Increased cost |

Smoother finish on soft materials | Reduced chip load |

Higher feed rates |

Up-cut end mills pull chips up and away from the cutting area. This helps keep your surface clean and prevents chips from scratching your workpiece. You can use air blasts or coolant to clear chips and improve your finish. Efficient chip evacuation also removes heat, so your tool lasts longer.

Tip: Always clear chips from the cutting zone to avoid scratches and smearing.

Down-cut end mills push chips down into the material. You’ll want these for woodworking, especially when you need a clean top surface. They prevent splintering and tear-out, which is perfect for cutting veneers, thin plywood, or making grooves.

V-bit end mills have a pointed tip. You’ll use them for engraving, chamfering, and making sharp corners. They’re great for adding detail to signs, molds, or decorative pieces.

End mills come in many shapes, including bull nose, roughing, V-bit, and flat end mills.

You can create holes, slots, and profiles with the right type.

When you pick out tools for your CNC machine, you’ll notice a few main materials. Each one changes how your tool performs and how long it lasts. Here’s a quick look at what you’ll find:

Material | Characteristics | Performance Impact |

High-Speed Steel (HSS) | Tough, affordable, handles shock loads | Good for general jobs, but wears out faster |

Cobalt | Handles heat better, stays hard | Works well on tough materials, lasts longer |

Carbide | Super hard, resists wear | Perfect for fast, high-volume jobs, costs more up front |

You might wonder how carbide and HSS compare. Carbide end mills last three to ten times longer than HSS. They handle heat up to 1000°C, while HSS tops out at 600°C. Carbide keeps its edge sharp, but you’ll pay more for it. HSS costs less and works for short runs or softer materials.

Tip: If you run big jobs or cut hard metals, carbide pays off in the long run. For smaller projects or softer materials, HSS saves money.

Coatings give your tools extra power. They help your end mills last longer, cut cleaner, and handle tough jobs. Here’s a table to show what each coating does:

Coating Type | Benefits | Applications |

TiN | Resists wear, handles heat, works on steel and iron | Everyday machining |

TiAlN | Handles high speeds, resists heat and oxidation | Stainless steel, titanium, tough materials |

ALTiN | Extreme heat resistance, fights wear | Hard, aggressive milling |

DLC | Super hard, low friction | Composites, abrasive materials |

ZrN | Stops corrosion, adds lubrication | Precision aluminum work |

You don’t have to pick the fanciest coating every time. Think about your material and how fast you want to cut. For example, TiN works for most jobs, but ALTiN or TiAlN shine when you push your machine hard or work with tough metals.

Note: The right coating can double or triple your tool life. You’ll spend less time swapping out tools and more time making great parts.

Selecting the right tool for your CNC job can feel overwhelming, but you can break it down into a few key steps. Let’s walk through what you need to consider so you get the best results every time.

l Start by looking at what you’re cutting. The material of your workpiece shapes almost every decision you make about tooling. Here’s how different materials affect your choice:

l Softer materials like aluminum and plastics work best with 2-flute or 3-flute end mills. These tools have polished surfaces that help prevent chips from sticking.

l For steel and other hard metals, you’ll want carbide end mills with special coatings. These stand up to high temperatures and resist wear.

l If you’re working with composite materials, diamond-coated end mills help you avoid delamination and keep your cuts precise.

Tip: Always match the hardness of your cutting tool to the hardness of your workpiece. A harder tool lasts longer and gives you a better finish.

l Think about how smooth and accurate you want your finished part to be. If you need a tight tolerance or a shiny surface, you’ll need a tool designed for finishing.

l Finishing end mills use advanced materials like carbide or cobalt. These materials stay sharp and resist wear.

l Look for tools with more flutes—five or more is common for finishing. More flutes mean a smoother finish.

l High helix angles help move chips away and keep the tool cool, which improves your surface quality.

l Use finishing end mills for the final pass when you need crisp edges and exact dimensions.

Note: For aerospace or medical parts, always choose finishing tools that deliver both accuracy and a great appearance.

The shape and design of your tool matter just as much as the material. Geometry affects how the tool cuts, how long it lasts, and how much force it puts on your machine.

Flat-end mills are perfect for slotting and pocketing. They leave sharp edges and flat bottoms.

Ball nose end mills glide over curves and create smooth, rounded surfaces.

Roughing end mills remove lots of material quickly, making them ideal for the first stage of a big job.

You’ll also want to pay attention to the tool’s edge design. Advanced cutting edges help clear chips and reduce cutting forces, which means less wear and longer tool life.

Flutes are the grooves that spiral around your end mill. The number of flutes changes how the tool handles chips and how fast you can cut.

For shallow cuts, more flutes can help you get a smoother finish since chip evacuation isn’t as critical.

Deep cuts need larger flutes to clear chips quickly and prevent clogging.

Non-ferrous materials like aluminum often use 3-flute tools for better chip removal and higher productivity.

Ferrous materials like steel benefit from 5, 6, or even 7 flutes, which improve tool life and reduce wear.

As you add more flutes, the core of the tool gets bigger, leaving less space for chips. Always balance flute count with your chip evacuation needs.

l The size of your end mill affects both accuracy and stability. Here’s what you need to know:

l A larger diameter gives you more stability and less vibration, which means better accuracy.

l The longer your tool sticks out (overhang), the less rigid it becomes. Too much stickout can cause the tool to bend or chatter.

l Try to keep your tool stickout to no more than three times its diameter for the best results.

l The right diameter and length help you avoid tool deflection and keep your cuts precise.

l Your CNC machine has its own strengths and weaknesses. Don’t ignore them when picking your tools.

l Larger end mills need more horsepower. Stay within 80% of your machine’s power to avoid overload.

l If your tool sticks out too far, it loses rigidity. This can lead to bending or even tool breakage.

l Harder materials demand more rigid tools. Keep stickout short to prevent chatter and maintain accuracy.

Tip: Always check your machine’s specs before choosing a tool. A mismatch can lead to poor results or even damage your equipment.

The right coating can make a huge difference in tool life and performance. Match your coating to your material and cutting conditions.

Coating | Suitable Materials |

Bright | Aluminum, Titanium, Brass |

ZrN | Aluminum, Titanium, Brass |

TiB2 | Aluminum, Titanium, Brass |

AlTiN | Carbon Steels, Tool Steels, Alloy Steels |

TiAlN | Carbon Steels, Tool Steels, Alloy Steels |

Firex | Carbon Steels, Tool Steels, Alloy Steels |

TiN | Stainless Steel |

NaCRO | Stainless Steel |

TiCN | Stainless Steel |

l AlTiN coatings work well for hard materials and high-temperature jobs. They’re great for aerospace alloys and stainless steel.

l For aluminum and softer metals, choose coatings like Bright, ZrN, or TiB2.

l Some coatings, like AlTiN, perform best in dry machining and reduce the need for coolant.

Note: The right coating can double your tool life and improve your results. Don’t overlook this step!

When you take the time to match your end mills to your CNC needs, you set yourself up for success. Think about your material, finish, geometry, flute count, size, machine limits, and coating. Each choice brings you closer to a smoother, faster, and more reliable machining process.

Getting your feed rate and spindle speed right can make a huge difference in your results. You want to match these settings to your material and tool. Here’s a quick guide:

Material | Spindle Speed (RPM) | Feed Rate Tips |

Aluminum | Up to 10,000 | Use moderate feed rates for smooth, fast cutting. |

Steel | 2,000 to 6,000 | Try higher feed rates to manage heat. |

Titanium | Slower speeds | Go slow to prevent tool wear. |

l Always check the manufacturer’s recommendations.

l Use the chip load formula to balance speed and feed.

l Test and adjust until you see a clean cut and minimal tool wear.

Tip: The right speed and feed help you avoid chipping and get a better finish.

l You want your tools to last as long as possible. Tool life depends on several things:

l Cutting speed and feed rate: Too fast or too slow wears out your tool.

l Tool material and coatings: Harder tools with coatings last longer.

l Chip evacuation: Clear chips often to prevent damage.

l Coolant: Use coolant or lubrication to keep things cool.

l Machine condition: A well-maintained machine reduces vibration and tool wear.

Keep your setup stable and your tools sharp for the best results.

l Good chip evacuation keeps your cuts clean and your tools safe. If chips build up, you might see scratches, heat, or even tool breakage.

l Use air or coolant to clear chips from the cutting area.

l Pick end mills with the right flute count for your material.

l Avoid deep pockets without a plan for chip removal.

Chips left behind can cause tool damage and ruin your finish.

l Plan your cuts in the right order. Start with roughing passes to remove most of the material. Finish with lighter, slower passes for a smooth surface.

l Begin with larger tools for roughing.

l Switch to smaller, sharper tools for finishing.

l Check your tool path to avoid unnecessary moves.

Many people run into the same problems when using end mills. Here’s a table of common mistakes and how to fix them:

Mistake | How to Avoid It |

Chipping | Lower your feed rate on the first pass. |

Chip Packing | Use fewer flutes and more coolant. |

Excessive Wear | Slow down your speed and use coated tools. |

Burrs | Replace worn tools and adjust your settings. |

Poor Finish | Reduce feed rate and increase RPM. |

Short Tool Life | Check your speeds and use coated end mills. |

Stay alert for these issues and adjust your process to keep your project on track.

You now know how picking the right end mill can change your CNC results. When you match tool type to your project, you get smoother cuts and save time. Use this guide to avoid common mistakes and boost your machining skills.

Want to go further?

Explore advanced resources

Ask experts for advice

Keep learning new techniques

Smart choices lead to better parts and less stress. You’ve got this!

A 2-flute end mill clears chips faster, so you use it for softer materials like aluminum. A 4-flute end mill gives you a smoother finish and works better on harder metals.

Watch for dull edges, poor finishes, or strange noises. If you see chips sticking or the tool leaves burrs, swap it out. You’ll get better results and avoid damage.

You shouldn’t. Metal needs harder, coated end mills. Wood works best with straight or down-cut flutes. Using the wrong tool can cause rough cuts or breakage.

Keep your feed rate and speed in check. Use the right tool for your material. Clear chips often. If you notice vibration or chatter, slow down and check your setup.

By continuing to use the site you agree to our privacy policy Terms and Conditions.